Enhancing Item Appearances: The Function of In-Mold Decorations in Manufacturing

Understanding In-Mold Decorations: Approaches, Patterns, and Best Practices for Optimal Outcomes

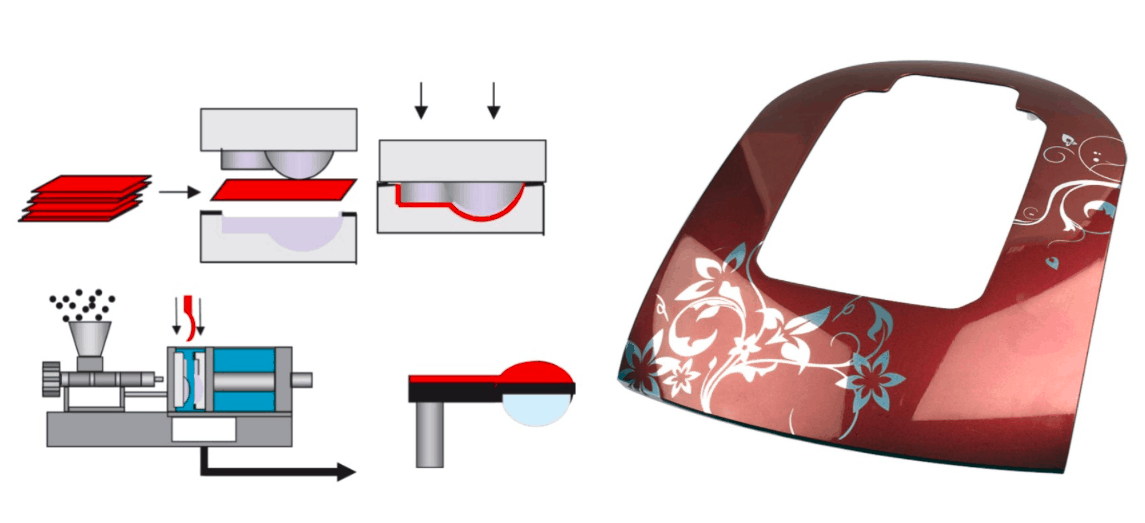

In the realm of production, the art of in-mold designs stands as a crucial element of product style and production. In-Mold Decorations. By diving into the approaches, fads, and ideal methods that underpin successful in-mold design procedures, organizations can unlock a world of opportunities that not only elevate the aesthetic appeal of their products but also improve manufacturing efficiency and strengthen consumer involvement.

Material Selection

Material option is a crucial aspect of mastering in-mold decorations, as it straight affects the top quality and durability of the end product. When choosing products for in-mold decorations, it is vital to think about aspects such as compatibility with the molding process, the preferred visual end result, and the environmental problems the product will deal with. Polycarbonate products like polycarbonate, ABDOMINAL, and polypropylene are frequently utilized for in-mold designs due to their adaptability and capability to attain detailed designs. These products use exceptional moldability, making it possible for manufacturers to produce intricate shapes and patterns with precision.

Furthermore, the selected material ought to have excellent adhesion residential or commercial properties to guarantee that the design sticks firmly to the substratum during the molding process. Attachment in between the product and the design is important for protecting against delamination and guaranteeing long-lasting aesthetic appeal. Furthermore, materials with high heat resistance are preferred for in-mold decorations, particularly for products that will be exposed to elevated temperature levels throughout their lifecycle. By very carefully selecting the ideal product for in-mold designs, manufacturers can boost the total top quality and resilience of their items, fulfilling the assumptions of both customers and end-users.

Layout Development

An essential consider progressing the area of in-mold decorations is the constant exploration and execution of style development methods. Style innovation plays an important duty in improving the aesthetic allure, functionality, and total top quality of items manufactured utilizing in-mold design processes. By incorporating ingenious design elements, makers can differentiate their items in the market, draw in consumers, and remain ahead of competitors.

Among the crucial elements of style development in in-mold decors is the combination of detailed patterns, appearances, and graphics that were formerly testing to attain with typical decor methods. Advanced innovations such as 3D printing and electronic layout tools enable designers to develop complex and comprehensive layouts that can be seamlessly moved onto shaped parts. Additionally, making use of vibrant colors, metal surfaces, and special effects like gloss or matte textures can further raise the aesthetic appeal of in-mold enhanced items.

Additionally, design development extends past aesthetic appeals to encompass useful enhancements such as ergonomic shapes, integrated attributes, and adjustable components that satisfy details user needs. By embracing style development, makers can open brand-new possibilities for creativity, customization, and product differentiation in the competitive landscape of in-mold decorations.

Manufacturing Effectiveness

Efficient manufacturing procedures are essential for translating the innovative designs established in the area of in-mold decorations right into high-grade completed products that fulfill market needs and consumer expectations. In the realm of in-mold decorations, manufacturing efficiency incorporates numerous crucial elements that add to the general success of the manufacturing process.

In addition, carrying out automation and robotics in the assembly line can dramatically boost efficiency by simplifying recurring jobs and lowering the margin of error. Automation not just speeds up the manufacturing process but also improves accuracy and repeatability, bring about an extra consistent and top quality end item. Moreover, taking on lean manufacturing concepts, such as just-in-time inventory administration and waste decrease strategies, can even more boost production effectiveness by lessening downtime and maximizing source usage. Generally, an alternative technique to production effectiveness is paramount in taking full advantage of the possibility of in-mold design methods and accomplishing optimal results in the affordable market landscape.

Top Quality Control Actions

What are the crucial techniques for ensuring stringent top quality control actions in the world of in-mold decors? Quality assurance steps are vital in in-mold design processes to make sure the production of top notch and flawless finished items. One critical approach is the implementation of extensive inspection protocols at every stage of the production procedure. This involves conducting thorough aesthetic examinations, dimensional checks, and shade consistency analyses to determine any kind of defects or inconsistencies early.

Making use of sophisticated modern technologies such as computerized evaluation systems can also enhance the quality control process by offering accurate and reputable information for evaluation. These systems can discover imperfections that might be missed out on by hand-operated assessments, consequently improving total item top quality and consistency.

Routine training and growth programs for employees associated with the in-mold decor process can likewise add to keeping premium requirements. By enlightening personnel on finest practices, top quality assumptions, and the value of attention to information, business can foster a culture of high quality consciousness throughout the organization.

Customer Charm

To improve the marketability of in-mold design items, understanding and providing to customer choices play a crucial duty in identifying their allure and success. Offering personalization alternatives such as personalized styles, shade variants, and textural aspects can significantly enhance the appeal of in-mold design products.

Final Thought

In-mold designs supply a effective and flexible way to enhance item aesthetics. By very carefully choosing materials, welcoming ingenious layouts, optimizing manufacturing procedures, applying quality assurance actions, and prioritizing consumer allure, official website makers can achieve optimum outcomes. It is critical for business to continuously adapt and enhance their methods to remain competitive in the market. In-Mold Decorations. Grasping in-mold designs needs an all natural technique that considers all facets of the production process to make certain success.

In the realm of production, the art of in-mold designs stands as a critical aspect of item style and manufacturing. Layout development plays a vital duty in improving the aesthetic allure, capability, and total high quality of products produced utilizing in-mold decoration processes.One of the crucial elements of layout development in in-mold decors is the assimilation of complex patterns, textures, and graphics that were previously testing to accomplish with conventional decor approaches.Reliable manufacturing procedures are vital for equating the innovative designs developed in the area of in-mold decorations right into high-quality completed products that meet market demands and check here customer assumptions. Supplying personalization options such as customized styles, color variants, and textural aspects can dramatically improve the appeal of in-mold decoration products.